Here's something that's hopefully a little more interesting than posts about cutting circles and rectangles...

While looking around ebay for the remainder of my busker needs, I found someone selling plexiglass/lexan in small sheet and circles. Since I'm not that great at cutting lexan, the idea of using a 7" circle interested me and started me thinking of options for the pressure box window where you can look down and see the punched music roll passing by. Using the rounded rectangle window as laid out in the plans would have meant that a lot of the lexan would be "wasted" inside, unless I resorted to cutting it.

Since I'm hoping to give a vintage look to my busker, I thought it might be nice to have a more ornate type of window, so I started looking around google images pages for something that looked right.

After about 2 hours of searching using various keywords, I came across an image I really liked:

I took this into Photoshop and stretched it a little, resized it, made it symmetrical, and turned it into a stencil with horizontal and vertical centerlines for alignment:

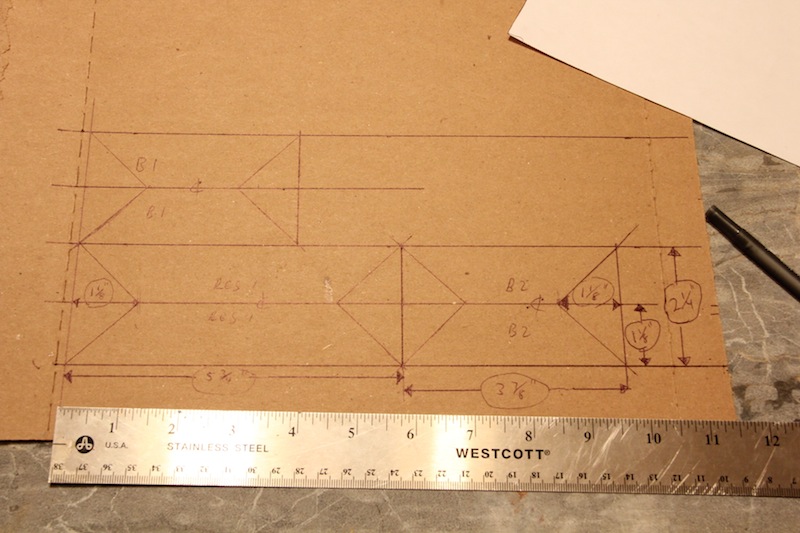

I printed out a couple of copies and experimented with a piece of scrap wood to see if the pattern was something I could handle on the scroll saw. After encouraging results, I assembled my supplies - Ruler, square, pencil, stencil pattern, spray adhesive, pressure box lid piece, "FrogTape" (painter's tape), scissors, needle files and sandpaper:

Then I covered the top of the pressure box lid piece with FrogTape, trimmed the stencil pattern and took it outside to apply spray adhesive to the back of it, then stuck it in place on top of the tape covered lid piece.

I had drawn alignment lines in pencil on top of the FrogTape to match up with the corresponding alignment marks on the stencil pattern.

I also covered the back of the board with some tape to prevent excessive splintering of wood (or so I hoped) from the action of the scroll saw on the plywood veneer edge. (In hindsight, I should have covered the entire back surface with tape, since the uncovered areas got fairly dirty with all of the scroll saw handling and rubbing.)

I then had to drill holes in each of the stencil cutout areas so I could feed the scroll saw blade up through the material before clamping the blade for cutting. 22 holes altogether.

Then I set to work carefully cutting out each part of the stencil.

It soon became apparent that my scrollsaw was on its last legs, so I set out to Sears to buy a new one. I had some less-than-perfect Christmas gifts to return at Sears, so with my store credit for the returns, the new saw only set me back about $60. (I don't really consider this an "organ expense" since tools are more like an investment - with this in mind, I should probably revise my first post about supplies and expenses.)

Here's some cutting with my new cheapie Craftsman scrollsaw:

It took anywhere from 5 to 30 minutes to cut out each section...

After a break for some leftover Christmas turkey, mashed potatoes, stuffing and gravy, I'm back at it into the night, aided by my trusty SnakeLight.

After the cutting is complete, here's what the front looked like:

And the back (with its grimy smudges):

Now ready for cleaning with the needle files and sandpaper:

This ought to look nice with a music roll running below it.

Time to move on to something else now...